Our solution

Assessment of exposure to airborne nanomaterials is performed by a pragmatic, tiered approach.

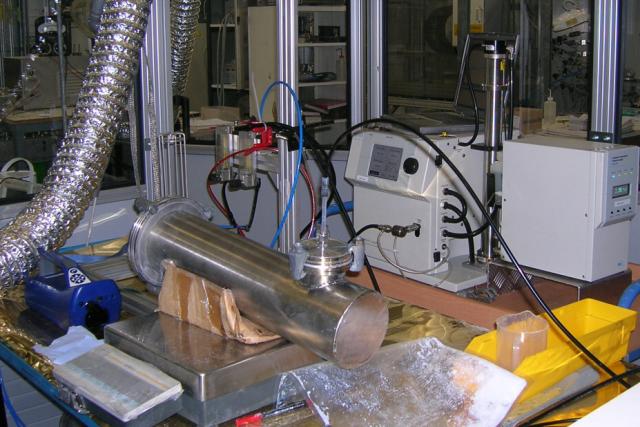

State-of-the-art equipment for physicochemical characterisation of nano-aerosols

Toggle all items

Assessment

Step 1 Potential for nanoparticle exposure

Information gathering (desk & walkthrough survey):

- Nanomaterials involved

- Process & maintenance

- Workers tasks

- Sources of incidental/process particle emission

- Exposure controls

- Ventilation

Screening measurements

Easy-to-use instruments to identify points of particle emission

Evidence of exposure

Step 2 Basic exposure measurements

- Limited number of user-friendly instruments

- Characterization emission source during activity

- Background levels

- Sampling and chemical analysis

Concentration level significantly increased over background

Step 3 Comprehensive exposure measurements

- Collection of particles for physico-chemical characterization

- Real time measurements with sophisticated instruments (particle number, size, surface area, mass )

Take additional risk management measures to mitigate exposure (precautionary principle)

Services

Nano aerosol exposure assessment in occupational settings

- Source identification

- Determination of worker exposure in occupational settings

- Contribution to safe innovation (Exposure scenario's, exposure Measurements, Risk Management Measures)

- Implement Control Banding Tools