3D printed nanoparticle-bearing systems for chemistry and energy applications

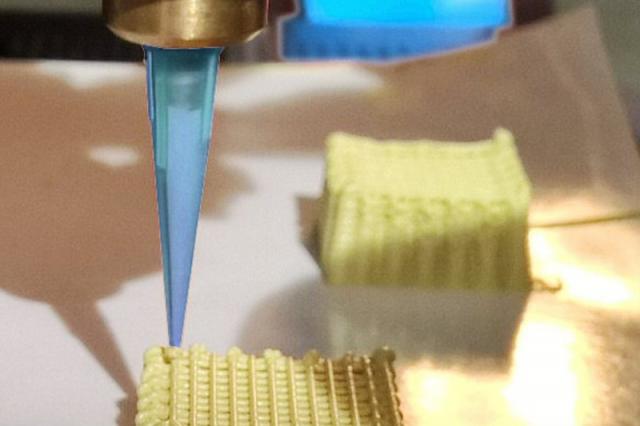

The burgeoning demand for 3D printing technologies is due to their suitability as a means of controllable deposition of support and active (nano)material in order to produce structured arrays. By employing existing and emerging 3D printing technologies such as 3D fiber deposition, repeatable dispensing and binder jetting, we tailor the macro- and microstructure of the support and nanoparticle precursor distribution. We managed to directly (co-)print and pattern a variety of ceramic and metal nanomaterials that showed the potential to achieve optimal functionality and design of the multi-component devices. Some of the examples include: carbon, graphene oxide, Al2O3, SiO2 CeO2, ZrO2 supports in polymer matrix as well as metal oxides and nanocomposite catalysts, adsorbents, electrodes and fuel cell materials. In addition, pertinent morphological and chemical information on support material and the nanoparticles is obtained by a combination of conventional and advanced characterisation.